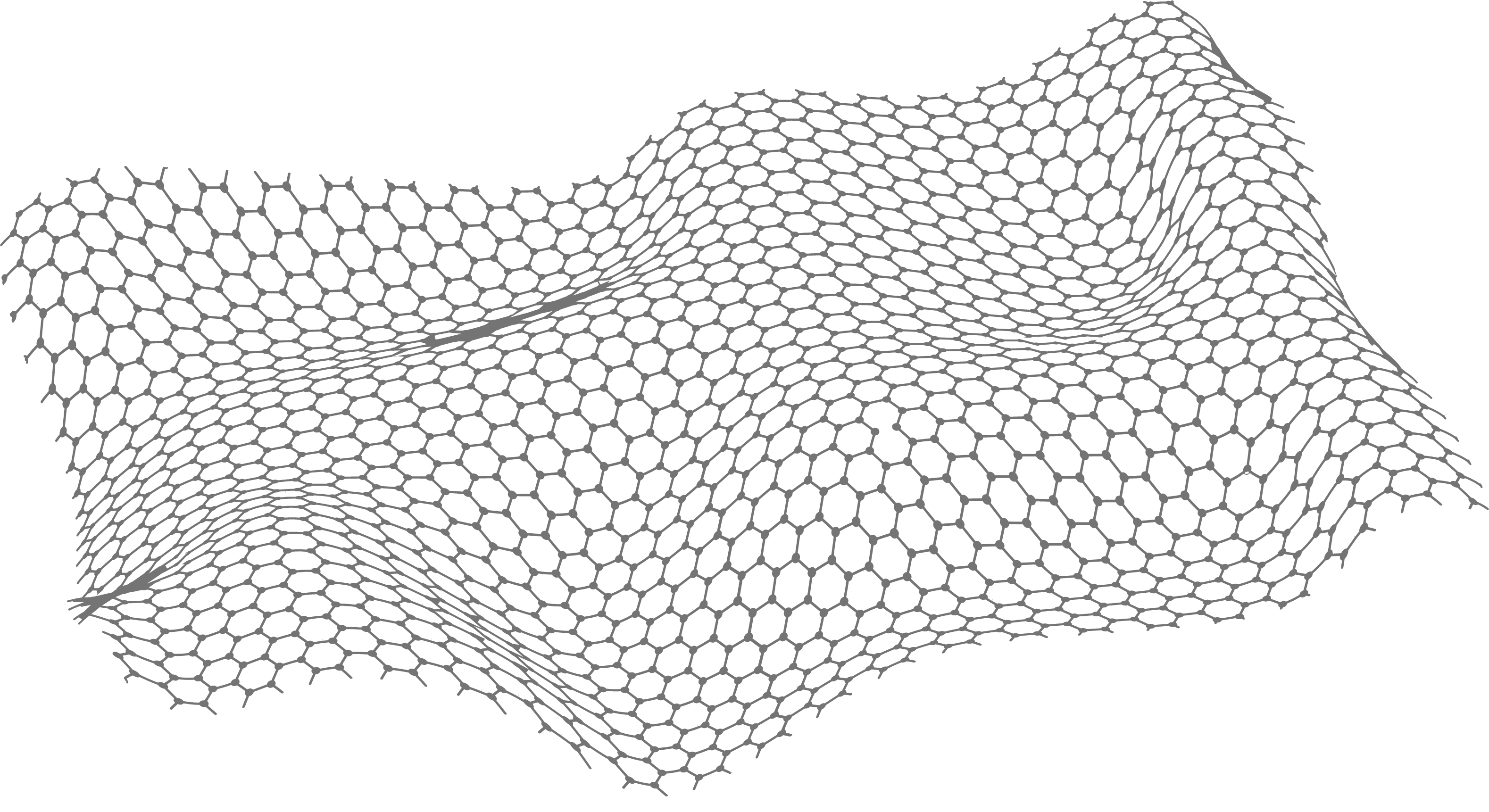

Graphene Composites: The Fundamentals

Graphene is a 2D material made of carbon atoms arranged in a hexagonal lattice which creates unique and powerful properties capable of transforming and disrupting global industries. When graphene is added to a base material, it imparts desirable properties including strength, flexibility, resilience, elongation, thermal and electrical conductivity as needed.

Here is a summary of graphene’s main attributes on composites:

One atom's worth of graphene is all that separates it from being a flat sheet. Strong covalent connections between the carbon atoms in the sheet form a lattice that resembles a honeycomb.

Graphene is exceptionally strong mechanically. It is one of the strongest materials yet discovered, with a tensile strength 200x stronger than steel. Additionally, due to its great degree of flexibility, it may be stretched without cracking.

Graphene is a super electrical conductor. It has a high electron mobility, which reduces the resistance faced by electrons as they flow through the structure. It is suitable to be used in electronics components.

The heat conductivity of graphene is very good. Graphene is advantageous for applications in thermal management, such as heat sinks or thermal interface materials.

Why Graphene is suitable in composites

Graphene is the strongest known material with many astonishing properties that can be useful in many applications. It has the ability to significantly improve various properties of the composites at very low loadings. When graphene is added to a base material, it imparts desirable properties including strength, flexibility, resilience, elongation, thermal and electrical conductivity as needed.

The Advantages of Graphene Composites

Improved Mechanical Properties: The high tensile strength, rigidity, and toughness of graphene contributes significantly to enhancing the mechanical strength, modulus, and toughness of polymer composites. For instance, graphene-reinforced polymer materials can improve the combination of lightweight and durability in composite materials used in vehicles.

Superior Electrical Conductivity: Because graphene is such a good electrical conductor, the composites that are produced can have a high electrical conductivity if required. Applications for this trait include electronics, sensors, electromagnetic interference shielding, and energy storage technologies. Polymers may be made electrically conductive using graphene reinforcement without losing other desired features.

Thermal Conductivity and Heat Dissipation: Graphene effectively dissipates heat due to its excellent thermal conductivity. Graphene increases the thermal conductivity of polymers and makes it possible for improved heat dissipation. Applications needing efficient thermal management, such electrical equipment or heat sinks, can benefit from this characteristic.

Improved Barrier Properties: Graphene reinforcement can improve the polymer’s ability to act as a gas and liquid barrier. A convoluted channel created by the peculiar structure of graphene sheets or particles prevents chemicals from permeating through the composite material. Applications for this trait include packaging, protective coatings, and barrier films.

Lightweight: Graphene is a very light substance. It aids in maintaining or even lowering the total weight of the material while also improving its mechanical qualities when employed as a reinforcement in polymer composites. This is particularly significant in sectors like aviation and automotive, where weight reduction is essential for enhancing performance.

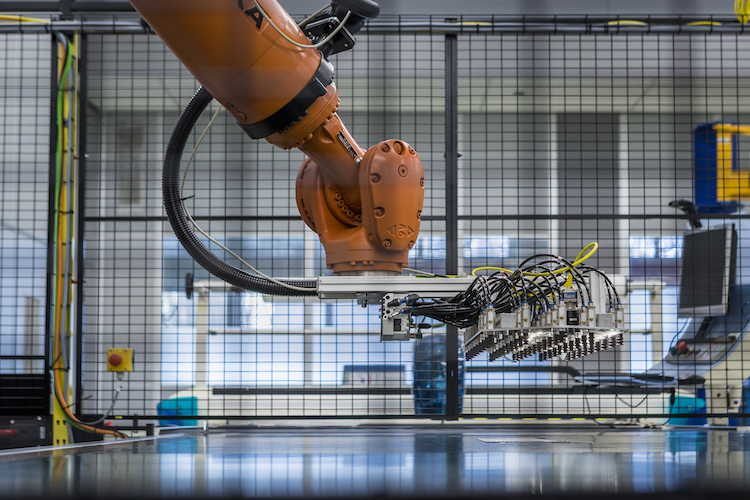

Flexibility and Processability: Reinforcement made of graphene may be added to polymers in a variety of ways, such as sheets, flakes or nanoparticles. Due to its adaptability, graphene may be incorporated into a variety of polymer matrices, allowing for flexibility in the production process. Extrusion, injection molding, and 3D printing are common methods for processing polymers reinforced with graphene.

Applications for Graphene Composites

Sparc's Expertise with Graphene Composites

Sparc has developed expertise and know how in the ability to add graphene to polymers typically employed in the Coatings industry. This expertise and know how is now being used to explore opportunities for graphene inclusion for polymers employed in the construction sector. In support of this objective, Sparc has joined Swinburne University in a 3 year research program aimed at delivering smart composites, i.e., enhanced polymeric systems that can also be monitored for performance in real time.

Other Projects

Focusing on adding functionality to selected grades of graphene in order to deliver targeted market solutions