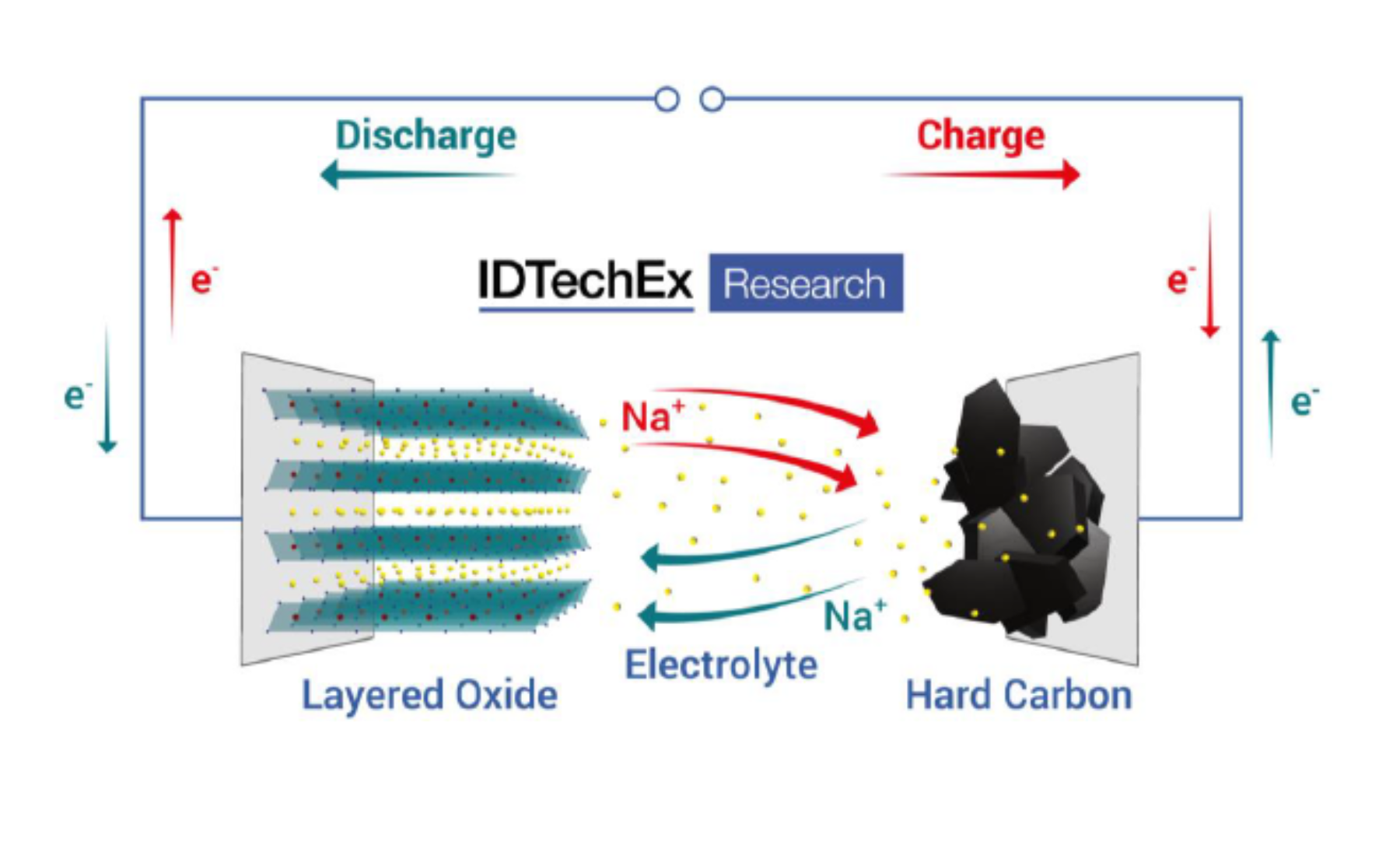

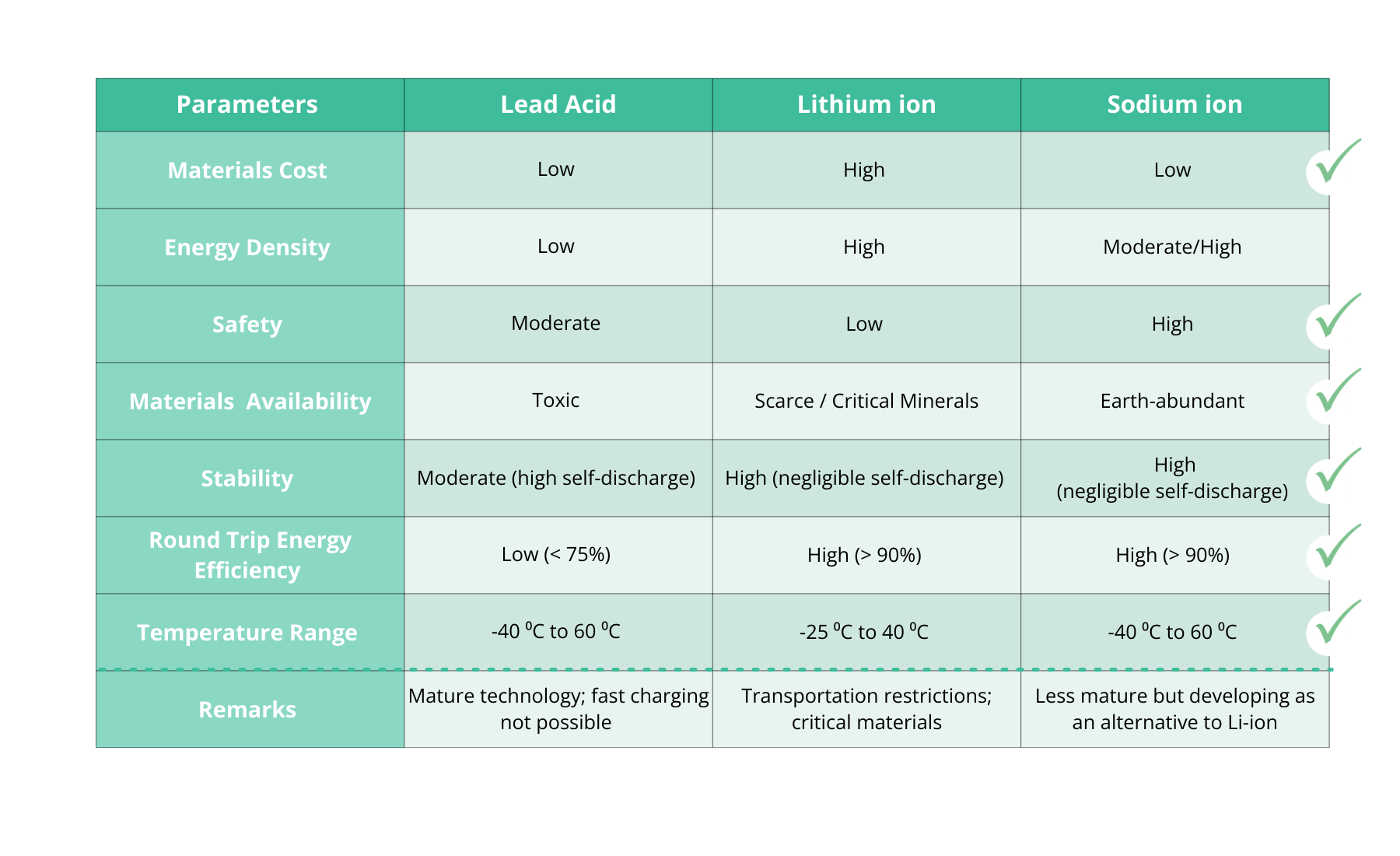

Introduction to Sodium-Ion Batteries

The sodium-ion battery (SIB) is a rechargeable battery that uses sodium ions (Na+) as its charge carriers. The working principle and manufacturing of SIBs is relatively similar to lithium-ion batteries (LIBs). However, what sets SIBs apart is the use of sodium in place of lithium as the cathode material and hard carbon in place of graphite as the anode material.

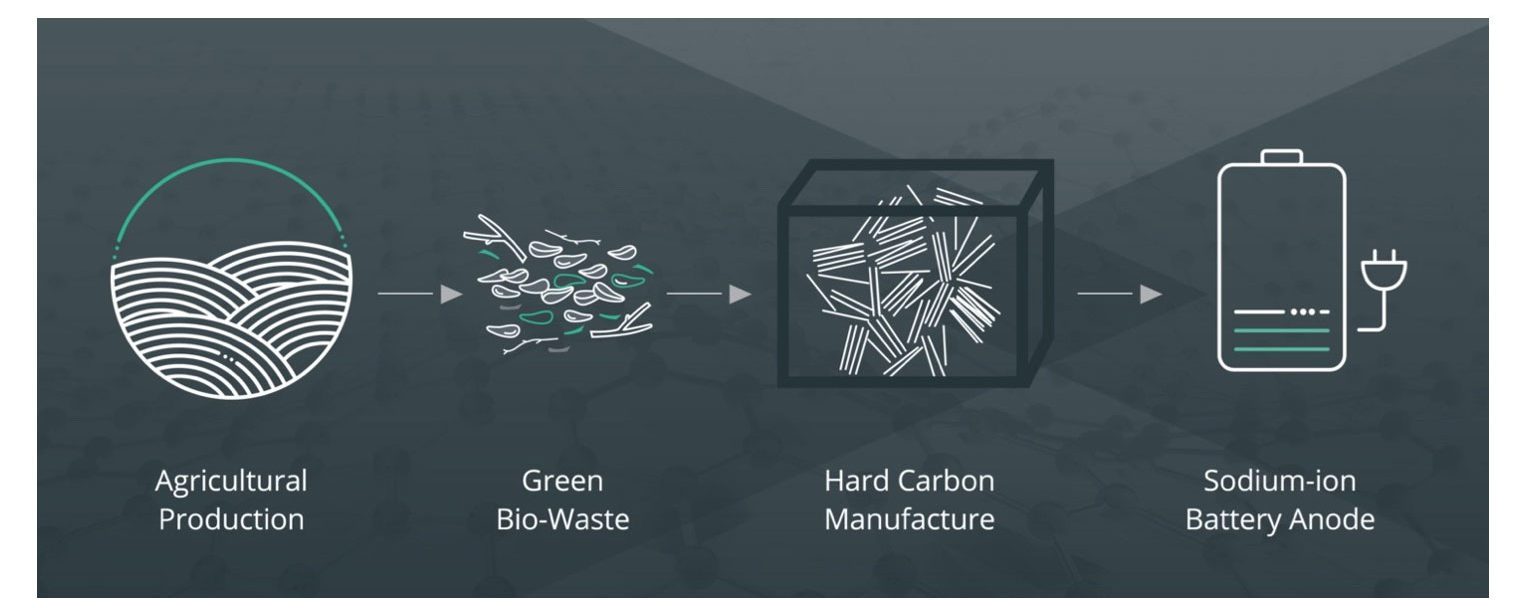

Sparc Technologies is developing a novel process for producing hard carbon from low-cost, sustainably sourced green bio-waste, shaping the future of eco-friendly energy storage solutions in Australia. Sparc is among the only listed companies in Australia developing sodium-ion battery materials.

Advantages of sodium-ion batteries

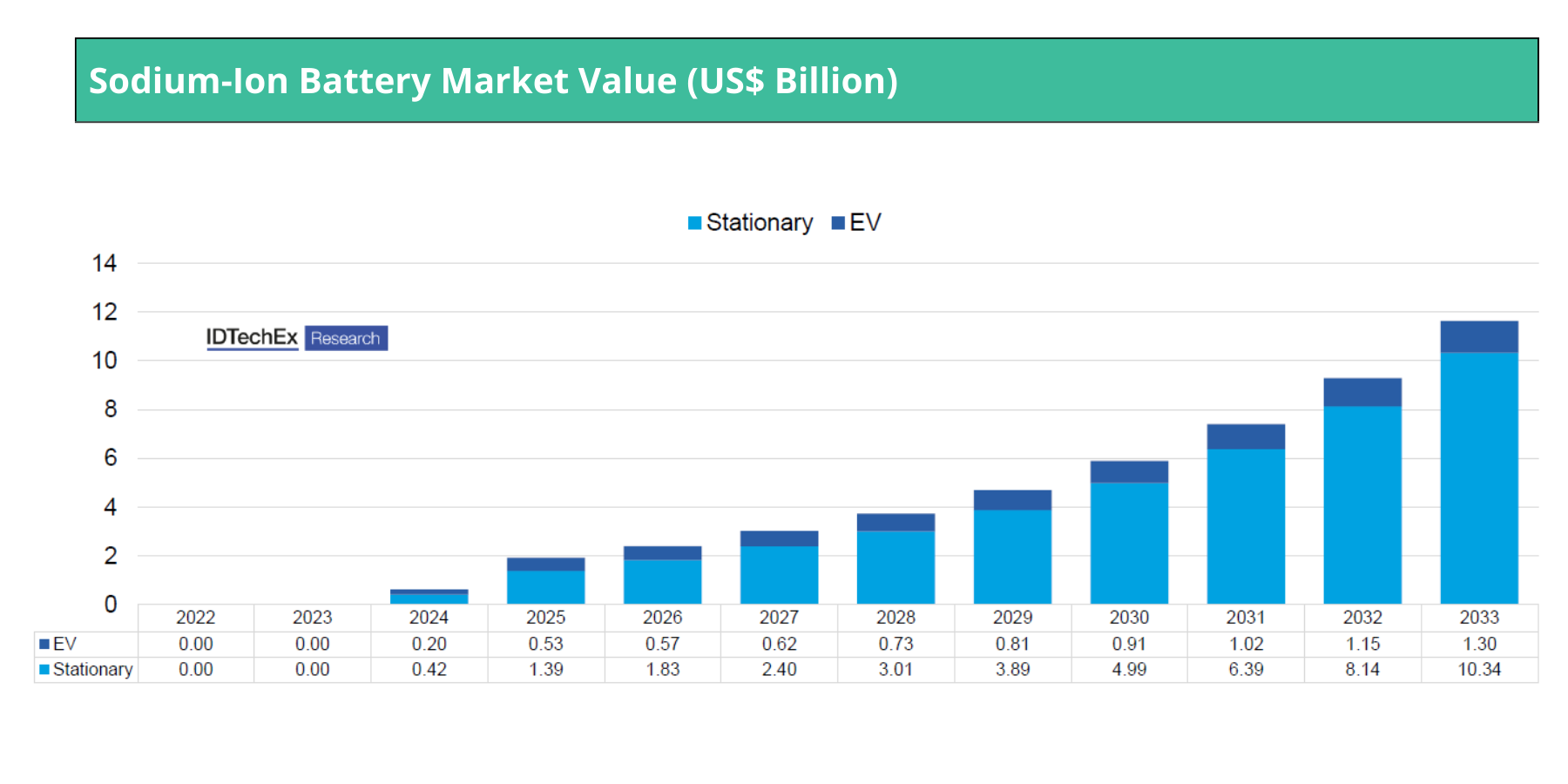

Sodium-Ion Battery Market Forecast

According to IDTechEx research, the market value for SIBs is expected to grow to US$11.6bn in 2033 (39% CAGR) driven by rapid uptake in stationary storage and light-duty EV applications.

The corresponding market demand for anode, cathode, and electrolyte materials for SIBs will also grow alongside it.

Benchmark Minerals Intelligence sees challenges in the supply of hard carbon to meet the rapid growth in the SIB industry noting that for 2025, even in their high production case, hard carbon capacity amounts to less than a third of the market requirements for SIBs.

Sustainable Hard Carbon Anode Project

A high performing, low cost, sustainably sourced anode material for Sodium ion batteries is meeting a need for what is a growing alternative battery technology. Existing hard carbon materials are typically sourced from carbonaceous precursors such as pitch (a by-product of the oil & gas industry) which undergo lengthy heating at high temperatures. This is a very energy consuming process which combined with a high emission feedstock has significant environmental impacts. Furthermore, with China being the world’s predominant supplier of hard carbon materials, this technology aims to provide an alternative western supply source thereby reducing sovereign risk for cell manufacturers

Sparc is developing a novel process to produce high performing hard carbon anode materials for sodium-ion batteries from agricultural biowaste.

Key features of the process under development include:

- Low cost, sustainably sourced green bio-waste feedstock.

- Faster, less energy intensive processing.