Sparc's Expertise with Graphene Composites

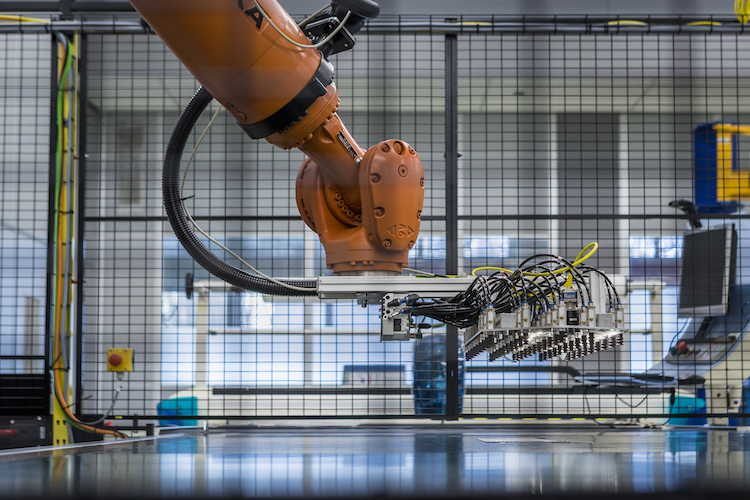

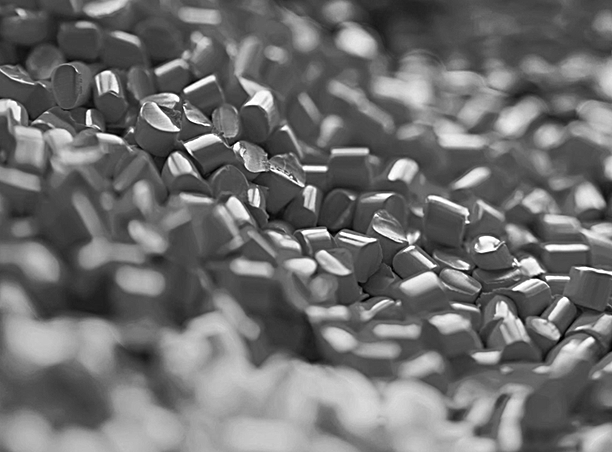

- Sparc has developed expertise in the ability to add graphene to polymers typically employed in the plastics and composites industries. Sparc has demonstrated performance improvements working with graphene enhanced solid polymers including increased strength, elongation, flexibility and both thermal and electrical conductivity. We’re currently seeking industrial partners from the plastics and composites industries who want to explore the power of graphene within their products.

Graphene Composites: The Fundamentals

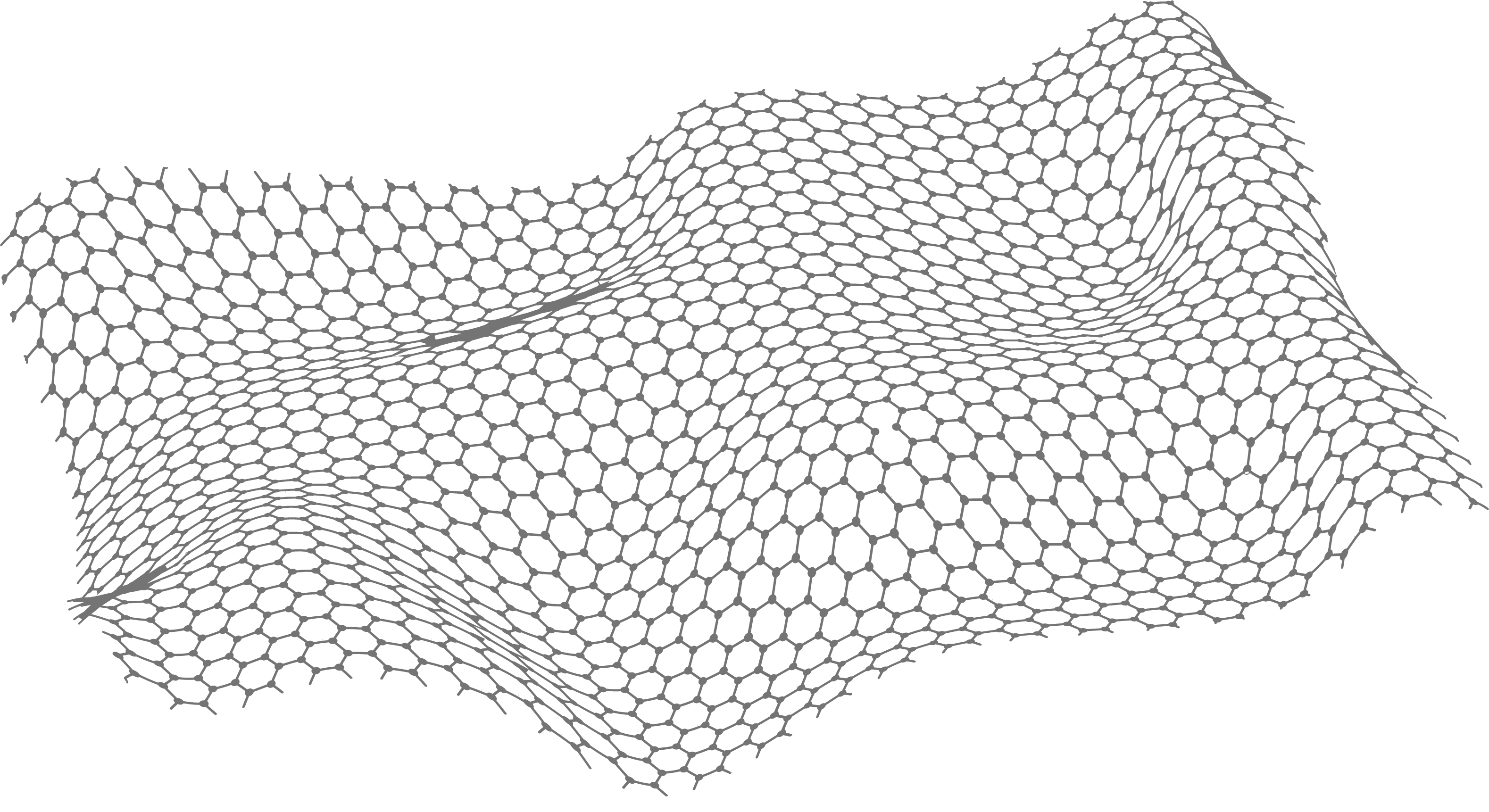

Graphene is a 2D material made of carbon atoms arranged in a hexagonal lattice which creates unique and powerful properties capable of transforming and disrupting global industries. When graphene is added to a base material, it imparts desirable properties including strength, flexibility, resilience, elongation, thermal and electrical conductivity as needed.

Here is a summary of graphene’s main attributes applicable to composites:

One atom's worth of graphene is all that separates it from being a flat sheet. Strong covalent connections between the carbon atoms in the sheet form a lattice that resembles a honeycomb.

Graphene is exceptionally strong mechanically. It is one of the strongest materials yet discovered, with a tensile strength 200x stronger than steel. Additionally, due to its great degree of flexibility, it may be stretched without cracking.

Graphene is a super electrical conductor. It has a high electron mobility, which reduces the resistance faced by electrons as they flow through the structure. It is suitable to be used in electronics components.

The heat conductivity of graphene is very good. Graphene is advantageous for applications in thermal management, such as heat sinks or thermal interface materials.

Due to its adaptability and 2D structure, graphene may be incorporated into a variety of polymer matrices, targeting improved flexibility in the production process.

Graphene reinforcement can improve the polymer's ability to act as a gas and liquid barrier.